TRAPALEN® - reaching the goal layer by layer

Our manufacturing process allows for the production of TRAPALEN® film in strengths ranging from 75 to 200 µm.

Our manufacturing process allows for the production of TRAPALEN® film in strengths ranging from 75 to 200 µm.

During the production of Trapalen®, several layers of thin OPP film are laminated to form a thick film without the use of adhesives or solvents. This is done on a thermal laminating system with the use of pressure and temperature. In this way, Folien Point produces film in thicknesses of between 75 and 300 µm. Stronger film can also be produced to meet customers' needs.

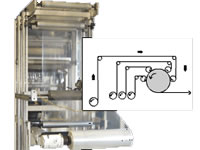

The central part of the system is the thermal laminating unit. This is where several layers of thin primary film are laminated to form a multi-layered film.

Following the rotating direction of the laminating drum, the first and last of the accumulating primary layers of film form the outer layers of the multi-layer film. The sealing layers of the primary film are heat-sealed together.

Following the rotating direction of the laminating drum, the first and last of the accumulating primary layers of film form the outer layers of the multi-layer film. The sealing layers of the primary film are heat-sealed together.

The introduction of the required heat is crucial for the success of the process. The necessary temperature is supplied by the heatable presses and the laminating drum as well as by additional infrared radiators that are aimed directly at the space between the press and the laminating drum.

After the last press station, the multi-layered film has reached its final thickness, is cooled, wound up and is immediately ready for further processing.